|

Introduction:

This is a description of the procedure I

performed trying to make a high-impedance-high-sensitivity earphone

set. The

idea was to combine the advantages of high

impedance vintage phones with the high sensitivity of an

balanced-armature

construction. I was more than satisfied with the results and I would

like to

share my experience with other DX enthusiasts.

I’ve have several DLR-5 earphones and

I

decided to rewind the spools of one pair.

First I tested their

characteristics and here

they are (per one element):

DC-resistance..............................27

Ohms

AC-impedance at 1

kHz............280 Ohms

Sensitivity at 1

kHz..................0.13

picoW

It wasn’t easy at all, but I am sure, with the

patience and enthusiasm you can also do this.

Before you

start,

keep in mind:

Don’t

rush, take your time!

Don’t

panic if something goes wrong! Almost

everything is reparable (see also the section troubleshooting).

Keep

dust and small particles away.

Control

every step as it is done

Never

solder or de-solder the coil contacts

with the permanent magnet in place because of the strong alternating

magnetic

field of the soldering iron.

Use

magnifying goggles.

Part 1 – Disassembling The

Element

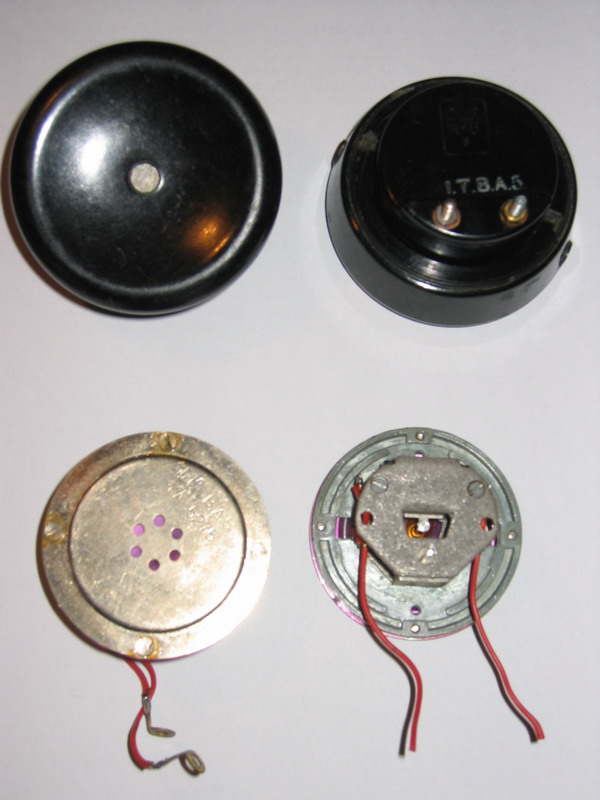

At fig.1 you can see the front and rear of the

original DLR-5 earpiece, in- and outside the housing.

Fig.

1

When

taking the element out, you should better

unscrew the contact screws than desolder the leads in such a small

space and

near the magnet.

After

loosen the three screws on the top, first

remove the magnet and then the upper plate of the magnet unit. It is

very

difficult to work within the strong magnetic field and there is the

risk of

damaging the armature.

Pull the

leads out of the eyelet of the lead

holder. Do not desolder the leads from the coil yet! The ends are wound

around

the coil contact plate.

Unscrew

the tiny nut from the drive rod using

fine but strong forceps like those shown at Fig. 2. (Bent microsurgical

or the depilation

forceps).

Fig 2

Remove

the coil, with the armature still

inside straight upwards, to avoid damaging the drive rod.

Bottom

plate of the magnet unit has to be

removed only if you should clean it from the hardened varnish. It is

important

to clean it because the varnish can later interfere with the

reassembling the

coil, damaging the wire, or can break and the particles can fall into

the

diaphragm space or between the armature and the coil.

The

diaphragm, drive rod and the second nut

you should leave in place. Try not to touch the lower nut, because it

determines the central position of the armature.

All

parts

are shown at the fig. 3.

Fig 3

Important: the two tiny ”U”-shaped parts,

marked with the arrows at the photograph (fig 3), are the only two

fixation

points of the armature, and they also determine the distance between

back end

of the armature and the poles of the magnet unit. Remember the position

of the

two pieces before removing the armature from the coil form and don’t

loos them!

Part 2 –Preparing The Coil Form

At

the coil form, you see two contact-plates

with lead contact and coil-wire contact each.

Using two

pairs of tong, as shown at fig. 4,

bend them straight or a few degrees further. Don’t hold the coil; the

form can break

by bending!

Fig 4

Now

remove the original wire. (You can keep

it, just in case you decide to undo the whole job!) ) and clean the

coil form

from the varnish. Also clean the soldering points.

Remove

the isolation from the contact plates

and polish them as well as the edges of the form with the fine

sand-paper (#

360 or higher). The whole inner side should be smooth and without any

obstacles, otherwise it could catch and break the delicate wire later.

Fig.5

shows the form ready for winding.

Fig 5

Part 3 – The Wire

The idea of the whole project was to get

higher impedance and that means as much turns as possible. To achieve

that, you

need the thinnest wire you can get and maximum space for it.

The

wire

I used was enamel coated 0.05 mm from

a reed-relay activating coil. Another way is to order it via Internet.

I

ordered some by CONRAD (www.conrad.nl),

order nr. 60 75 09-06, cost 3.55 Euro

+p.p. One spool (cc 1500 m) is enough for pair of phones. Anyway, the

wire must

be solderable. The wires I use are shown at fig. 6. Available space is

limited

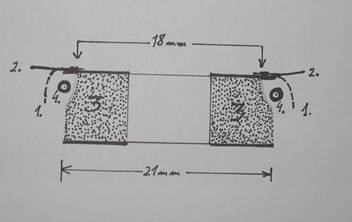

by the mounting rods, as shown at fig. 7. You can not stuff the whole

form

because of the clearance of 18 mm between the two mounting rods. The

drawing

also shows how you have to bend the contacts from their original

position

(marked 1.) to the temporary winding position (marked 2.). After winding, bend them back to the position 1.

See also fig. 4! Mark 3. is available

wire-space.

Fig. 6

Fig. 7

Part 4 – Winding

When

everything is ready, begins the real work

and excitement!

I

have

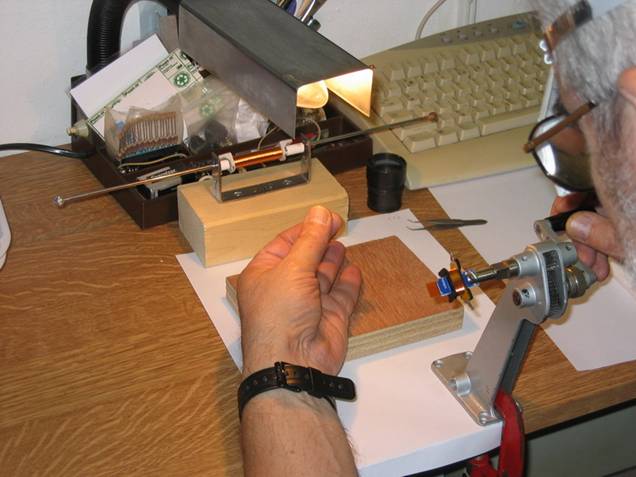

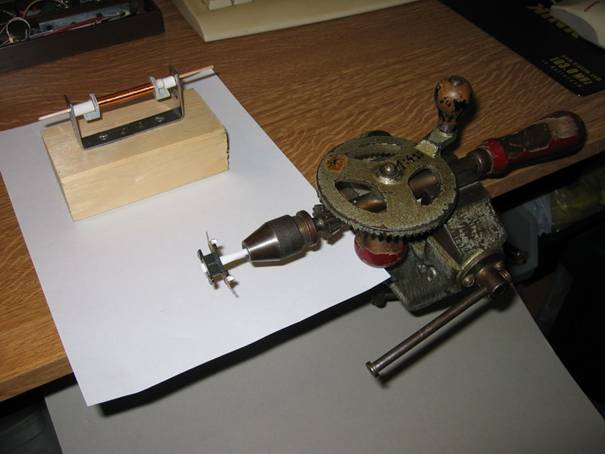

recently got a winding device for old

8mm films, shown at fig. 8.

Fig 8

You

can

also use a hand-drill fixed in the

claws, as I did for years (fig. 9).

Fig 9

It

is

very important to centre the form

perfectly, otherwise the windings can escape over the form edge.

Besides wearing magnifying goggles, do have a

bright spot light and put a white paper under the coil and the wire. It

is

important to see the wire and how you feed it. You can see better by

looking

with only one eye! Choose the direction

of winding so that the wire comes from upside the coil. The

source-spool must

also spin easily, without any resistance. With

your left hand, rested on the confortable height, you

lead the

wire, organise it within the coil, and keep it under a slight tension.

See fig

8. Try to organise the windings as good as possible, don’t make

criss-cross, it

takes unnecessary space. Try first a few layers to get some experience

and to

feel the maximal tension before breaking the wire.

Than cut

a few small strips of adhesive tape.

You shall need them to fix the wire at the coil if you have to make a

break for

any reason.

Secure the start by making a threefold loop of

4-5 cm and twist it. Bend it around the soldering contact (do not cut

it!) and

make the first few turns with such a strengthened twisted part and then

continue with single wire layers. Do the same with the end!

Mark at the paper every 100 turns if you do

not have automatic counter. You will later want to know how many turns

you have

put into the coil. You can calculate the total number of wire turns by

multiplying the number of drill-handle turns with the turn-ratio.

After

finishing the winding, solder the ends

and protect the windings with a 7mm wide strip of thin elastic adhesive

tape,

or a thin layer of a transparent nail-polish.

Control the clearance for the two mounting

rods, it should be 18 mm. Also control with the Ohm-meter if the

contacts are

good. The DC resistance should be between 1500 to 2000 Ohms.

Part 5 –

Reassembling The Element

Clean and

check all parts prior to reassemble

the unit in opposite sequence. That means the bottom plate first. Slide

the

armature in the coil with small hole facing the contact-side. Than put

the coil

(with the armature inside and the two small fixation

“U”-shaped parts in place), vertically into

the bottom plate so that the poles fit into the special grooves on the

coil

form. The drive rod must pass through the small hole of the armature,

and two

fixation pieces must lay at the pole of the magnet unit bottom plate.

Now

put

back the upper nut of the drive rod

and fasten the armature.

It

is of

crucial importance to check if the

armature is free and at equal distance on both sides within the central

slit of

the coil form!!! If not – adjust with

both nuts and tighten it. Remember that the vibrations of the armature

have to

be transferred to the drive rod and finally to the diaphragm. When you

put back

the upper plate, adjustment would be very difficult, if not impossible.

When

everything is OK, put back the upper

plate so that the poles fit into the upper grooves of the coil form.

Put the

screws back, but don’t fasten them yet. First slide the magnet back and

than

fasten the screws.

Pull the

leads through the eyelet of the

lead-holder and check once again if the armature is at central

position. If you

look through the coil against the light, you should see equal spacing

between

the armature and the poles of the magnet unit. Also check if the lead

contacts

are not touching the adjacent metal parts.

Now

put

back the contact-screws and fix the

element into the housing.

Connect

the flexible cable and the head-band

and...finally you’ve got it! (Fig 10)

Fig 10

Part 6 – Testing The Phones

To

check

the presumed characteristics you can

test the phones or simply compare with another set you have.

I rewound two elements and tested the

headphone-set using the following instruments: PHILIPS LF Generator PM

5100,

PHILIPS dual oscilloscope model PM 3207,

Digital AVO-meter Conrad Electronics M830B and analogue

Velleman Multitester 40000 Ohms/V.

There are

many procedures described on the Web

to test the AC impedance and the sensitivity. I

applied the one described by Dick Kleiert, with a small

variation: for

R1 I used 50 kOhms instead of 10 kOhms for better reading of the input

voltage

(200 mV).

Here are the

results:

- Windings

per

element................5300 + 5000

DC Set

resistance...................................3870 Ohms (2050 + 1840 )

AC Impedance at 1

kHz.......................56000 Ohms (pair)

Threshold sensitivity

at 1

kHz...........0.00028 picoW (pair)

The

term

“threshold sensitivity” has to

describe that I just was able to hear the 1 kHz signal in the compete

silence.

Of course, to understand the speech or music, you need more input

energy.

Part 7 –

Troubleshooting

In

spite

of all the attention and care there

is always something what can go wrong. Here are some situations, and

how you

can manage them:

Problem:

One

of the two “U”- shaped armature-fixation parts jumps off and you can

not find

it any more.

Solution:

Take

a 0.2 mm thin sheet of a non-magnetic metal and cut a strip 2mm wide

and 5 mm

long. Bend it around 0.6 mm, (that is the thickness of the armature) in

a

U-shape.

Problem:

Coil

form brakes.

Solution:

Cut

a piece 3 x 8 mm of thin (0.15-0.2 mm) pertinaks or similar hard non-

metallic

material and glue the patch from inside (wire-side) with cyanacryl glue.

Problem:

The

wire breaks.

Solution:

Fix the last layer at the

coil with

the

piece of adhesive tape and twist both broken wire-ends together. Solder

the

joint, cut it off to the length of about 2 mm and continue winding.

It’s no

need of any isolation (occupies the precious space), just cover it with

the

next layer of wire.

Problem:

You

loos the tiny nut of the drive rod.

Solution:

Try

to get one by the watch-maker or by an optician, or in some hobby-shop.

Take

the element with you to check the size.

Maybe it is a good idea to have one extra

(third) phone-element, just for the spare parts or to try again by

serious problems.

Part 8 – Epilogue

I

am

aware of the fact that my effort and the

result is not enough for a serious DX-work, but it is fun to try

something new.

Maybe I made some mistakes, in approach or by the testing. If anyone

does or

has done something similar, I would be grateful for any comments,

corrections

or confirmations. Also if you want some more information, mail me at d.mom@planet.nl

And

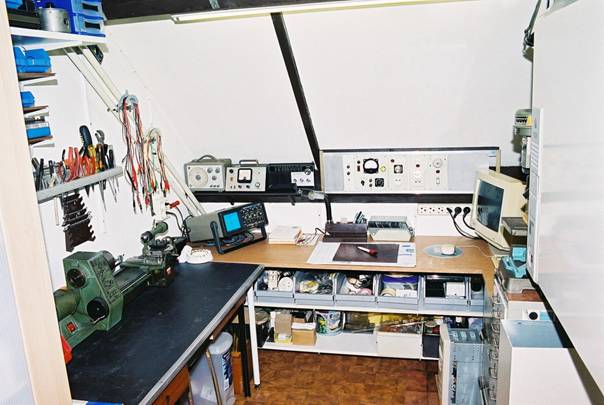

finally, fig. 11 shows my hobby-corner

where everything has been done.

Fig 11

Good luck,

Dejan

Rotterdam, October 2005

|